As a Six Sigma consultant I am often asked: “Have there been any Six Sigma deployments that have failed?” My answer is ambiguous enough to make me sound like a presidential candidate. That answer depends on your definition of the term “failure.” My definition of a failure would be a result that does not deliver the Return On Investment (ROI) anticipated by the company. Using this definition, I am not aware of any company that would admit to failed deployment. That being said we need to understand that any company that has invested the a significant sum of money and resources to do a Six Sigma deployment and made it public, it is highly unlikely they will admit they could not be successful, regardless of the outcome.

Most Six Sigma consultants typically define successful deployments in the following way: A successful Six Sigma deployment is one that provides an acceptable return to the business and leaves a stand-alone program, not requiring further consulting resources. I am not aware of a failure by this definition either. But most successful programs may have required some level of assistance once the consulting resources are gone. Most Master Black Belts, Black Belts and Green Belts will do what it takes to support the business in this case.

Most programs that have failed to deliver the exaggerated promises of savings (usually $250,000 per project per black belt trained (4 per year)), which are the result of the consultants’ salesmanship and the companies’ acceptance. The highest savings I have seen in a wave averaged $230,000 per project. This has been approached a few times and the average did not hold over the life of the program. Most deployments produce savings in the $100,000 to $200,000 per project range. This results from project selection. Using these criteria, it is very likely there have been many failures to meet expectations.Also, it is a fact of today’s business life that every Six Sigma deployment that has had some form of failure. A Six Sigma deployment is no different than any other business initiative. You make plans and develop metrics to evaluate the progress. When the deployment is not going as expected, you make adjustments.

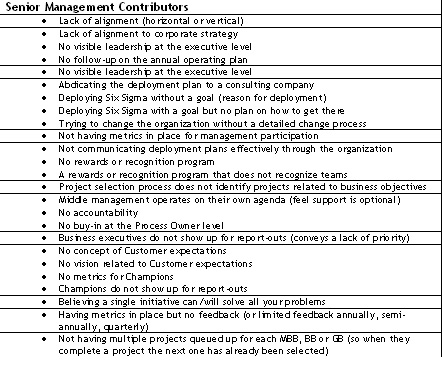

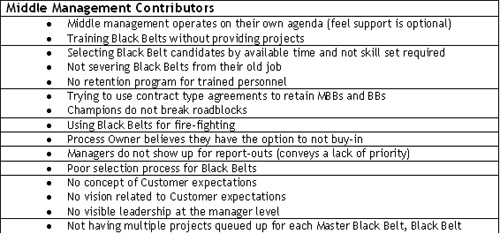

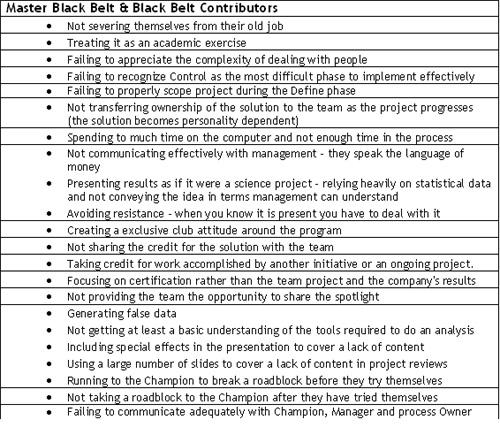

The following is just a partial list of the contributors to failure. They are numerous, complex, and interact.

The lessons to be learned are:

Lesson 1: Six Sigma Must Be Integrated with Business Strategy

Six Sigma techniques are powerful in reducing process variation. Today, an increasing number of companies are implementing a Six Sigma approach to business excellence as part of the business strategy.

Lesson 2: Six Sigma Efforts Must Support Business Objectives

Successful deployments are based on a “burning platform” – some major business challenge or risk that the company can overcome only through Six Sigma. It could be a need to regain competitiveness in the market, a need to introduce new services, attract new customers, retain existing customers or simply improve profitability. Identifying a burning platform means all the company’s business leaders are clear about why the company is adopting strategies based on Six Sigma principles.

Lesson 3: Key Executives Must Be Engaged in the Process

Two years into a Six Sigma deployment, one company did a review on its progress to date. The review included interviews with key decision makers throughout the organization. One of the more revealing interviews came from the vice president of product development – a key player in the organization. First, the vice president said, he had not been invited to attend any Six Sigma training, nor had any Champions or Black Belts asked him about his priorities. Second, he and his staff were keenly aware of all the money and effort being devoted to the Black Belts. The vice president and his staff had absolutely no reason to actively support Six Sigma, and instead had grown to view it with some resentment. By ignoring the importance of their commitment and support, the organization missed a prime opportunity to capitalize on all its resources.

Managers will never fully support Six Sigma if they view it as taking away from their resources rather than adding capability and helping them become more successful in achieving their goals; nor will they actively support it if they think it is eating up vital budgetary allotments rather than setting the stage for significant financial payback. To avoid such pitfalls, a company must involve all key business leaders in helping to design its Six Sigma deployment. By giving them a voice in project selection, priorities and ongoing monitoring, an organization can be assured of their commitment to the effort.

Lesson 4: Develop a Project Selection Process Based on Value Potential

If a company asks employees and customers for improvement suggestions, it will end up with many more ideas than it can possibly act on. The worst way to select which of these ideas to implement is to look at who made the suggestion, giving priority to ideas contributed by senior managers or ideas that are supported by a majority of leaders or employees.The most effective Six Sigma companies have a rigorous project selection process driven by an evaluation of how much shareholder value a project can generate. It can be characterized as a trade-off decision comparing value delivered to effort expended.

If a company asks employees and customers for improvement suggestions, it will end up with many more ideas than it can possibly act on. The worst way to select which of these ideas to implement is to look at who made the suggestion, giving priority to ideas contributed by senior managers or ideas that are supported by a majority of leaders or employees.The most effective Six Sigma companies have a rigorous project selection process driven by an evaluation of how much shareholder value a project can generate. It can be characterized as a trade-off decision comparing value delivered to effort expended.

Lesson 5: Find the Critical Mass of Projects and Resources

Some companies start their deployments by training a handful of people and launching a few “demonstration” projects. Others ramp-up for immediate corporate-wide deployment, training hundreds of Black Belts and launching dozens of projects within the first six months. Either approach is workable, but for every company there is a critical level of Six Sigma effort: Below that level, projects and focus eventually fade away. Above that level, excitement and momentum build into a sustainable advantage.

Lesson 6: Actively Manage Projects-in-Process

Given that most companies want to generate measurable, significant results within six months or a year, the tendency is to push as many projects into the Lean Six Sigma deployment as possible. But one of the most important lessons that Lean principles teach is that pushing excess work into a process slows down the process and dramatically increases lead times. As Six Sigma practitioners know, results can be speeded up by reducing the amount of work in process per Black Belt. That means controlling the number of active projects at any given time. It is better to focus on getting a few high-potential projects done right than to just flood the workplace with dozens of less-important projects. With the right resources working on the right projects, learning and results are maximized by short cycle times.

Lesson 7: Emphasize Team Leadership Skills

Use of Six Sigma does involve some technical skills – the ability to process and analyze data, for example. But good leadership skills are even more important. This emphasis on leadership also relates to how a company chooses people to fill Black Belt roles. Placing the most promising people in the Black Belt role is painful at first, yet it yields fast results and a rapid transformation of the organization.

Lesson 8: Track Results Rigorously

Six Sigma results should “pay as you go” and be confirmed by objective parties. Too many companies discount the necessity of having a reliable means to judge project results and impact, or they underestimate the difficulty in creating such a system. Six Sigma results must be quantified so a company can appropriately evaluate their impact and make good decisions about whether resources are being used wisely. A senior level finance person should participate in the development of a results-tracking rule book. As a deployment is planned, a company must think in terms of leading measurements or key performance indicators of the potential financial results. At a minimum, project cycle times and project values must be measured on a regular basis and to gain an understanding of the level of variation in these numbers.