There are many ways to ‘do’ business process improvement projects. It’s best if the company has a methodology from BPM, Lean, Six Sigma, Reengineering or some other methodology. Here’s the one I use, starting with selecting the project and ending with monitoring and sustaining the project; ‘doing’ the process improvement project means completing the section in the middle from Chartering and Staffing to Implementation Plan.

Companies use a number of methods to conduct the BPM project from using a Six Sigma Black Belt as an expert, to having a Business Analyst do interviews with subject matter experts and developing the as is model and to be map, to using different half day workshops for different phases of the process with the appropriate stakeholders. The one I highly recommend and have used with over 100 different processes is a team-based method.

I‘ve just used this method again with 6 different teams for a financial services client, and here’s what they saw as the advantages for them.

• The method combines skill building and real project work

• The method gets real work done on current projects

• Work is accelerated because the team combines modeling, analysis, data gathering and ongoing decisions

• The team includes different stakeholders that talk through their different perspectives • The different voices are in the same room together

• Quick wins are recognized early

• The team creates its own synergy and this leads clarity and enthusiasm about implementation

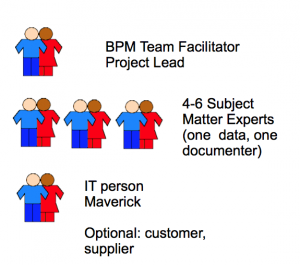

Here are the key roles on the team:

I call this the group of employees a team because the members have different roles of the process, and they represent the different stakeholders that do the work. Whereas other methods engage stakeholders in individual interviews, when you bring the group together as a team they act like a team – moving toward the Process Owner’s goals as represented in the improvement targets he articulates for the team in the charter. The team stays together for all meetings and begins to see the big picture; they learn to respect all parts of the process and develop the new ‘to be’ model based on their analysis, data gathering, and customer in put together. Their result is greater than each member alone, and their enthusiasm builds toward an optimum result. Each member learns many techniques that can be used in other projects, but the biggest result is the group effort to understand, analyze, and create a new improved process.