Introduction:

You’ve just been asked by your boss to develop and implement a productivity program to reduce waste and improve quality. Several of the executives are retrenching into a defensive posture: preserve cash, freeze discretionary spending, cut operating budgets X% across the board, accelerate early retirements, layoffs, and sell off non-core assets. Others are advocating more investment in R&D, rolling out new products / services, and even rethinking the business model. Your company’s livelihood is at stake. The expectations for you personally are even higher. Where do you begin? What kinds of Productivity / Quality programs are available? Which are appropriate for your business? How much of an investment is required? What’s the Return on Investment?

The choices and varieties of Process Improvement / Quality programs are bewildering: TQM, TQC, Lean, Six Sigma, Kaizen, Theory of Constraints, PDCA, ISO 9000, etc. It is easy to become confused and overwhelmed. They all have their advantages and short-comings. They all seem to require significant resources, infrastructure and time. What is your action plan?

At this stage, however, the primary focus should not be the type of infrastructure, or how many employees are trained, or how many projects you must complete. The emphasis should be how you can deliver value to the business. The good news is that there is no reason you cannot bootstrap a Productivity / Quality program and make it self-funding. If the program costs anything, something is wrong. Think of it as an investment upon which the organization and personal excellence depends. When implemented properly, it should yield a return of at least 10 to 20 times the investment in a few years.1 At this early stage, however, all that is needed is resourcefulness, creative thinking and “sweat” equity to implement.

Getting Started – An Action Plan

Step 1

– Talk to your customers! Nothing cuts through the noise and clutter better than talking directly to your customers (external and internal) to understand their needs, expectations, and critical-to-quality factors. These might include improved sales close rates, more reliable products / services, timely deliverables, reducing inventory levels, improving customer service, or accelerating Days Sales Outstanding. Twenty two years ago, I was working in Japan as a visiting M.I.T. scholar. As a young engineer, I was fortunate to meet Dr. Edwards Deming at the annual Deming Prize held in Tokyo. At the ceremony Deming did not speak about TQM, Six Sigma or Lean. What I remembered was his focus on the Customer and the importance of understanding their needs and expectations. Talking directly with your customers on a regular basis can provide meaningful insights into where to prioritize your efforts.

Step 2

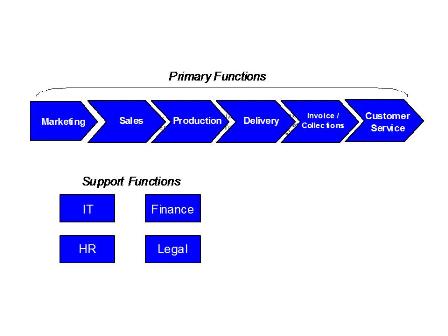

– Examine your company’s value chain: the primary and support business functions necessary to deliver products or services. At this stage, it is imperative to engage cross-functionally at all levels and take an end-to-end view of the large value chain processes that impact your business. Typical primary functions include: Marketing, Sales, Production, Delivery, Invoice / Collections and Customer Service. Examples of support activities include IT, finance, HR, and legal.

Figure 1

Figure 1

Work with senior management to identify the key metrics used to measure the performance of the business (i.e., Percent Sales Close Rates, Number Defectives per batch, Average Delivery Time, Number Inventory Turns per Year, Percent First Call Resolution, and Average Days Sales Outstanding). Compare your current performance metrics against your company’s goals and objectives. This will help to narrow down where you should concentrate your efforts.

Step 3

– Look across the organization’s key business processes that impact the value chain both upstream and downstream. Below are some fairly common key end-to-end business processes to consider:

- Promotion-to-Order

- Requisition-to-Receipt

- Demand-to-Availability

- Order-to-Delivery

- Purchase-to-Pay

- Order-to-Cash

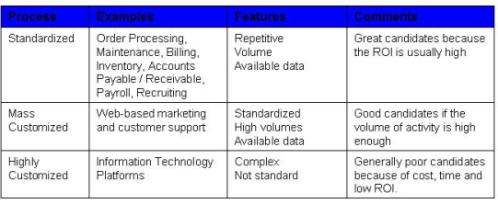

Determine which parts of the process are the best candidates for improvement projects. Figure 2 describes some basic sub-business processes within the larger end-to-end business processes2.

Figure 2

Figure 2

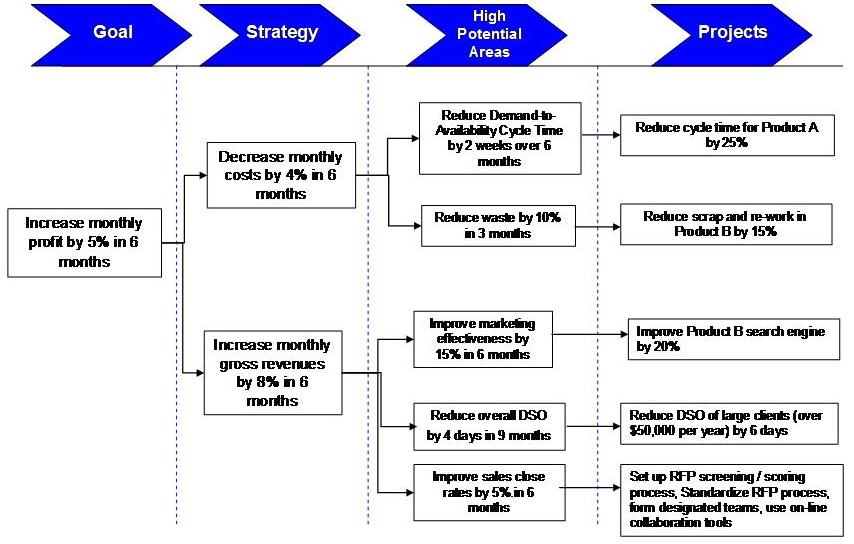

A more detailed approach for identifying the right projects is to perform an Enterprise Improvement Plan.3 It begins with identifying the goal(s) of the organization. From the goal(s), the appropriate strategies can be crafted. These strategies lead to identifying high-potential improvement areas and ultimately selecting and executing the right projects. This process “pulls” for the creation of specific quality / process improvement projects (“pull” used as lean term) that will drive the key goals / metrics. Although an Integrated Improvement Plan requires a thorough knowledge of your organization, it can be quite valuable.

|

Figure 3 – Click to view image (PDF)

The most important message is to focus on specific, achievable projects that are well-scoped and can be accomplished in a relatively short time frame. Don’t try to “boil the ocean” by taking on large, complex initiatives. I prefer projects that are more process-oriented in nature (i.e., can be improved through Methods & Procedures, training, clearer instructions, elimination of non-value steps, etc.) because they generally require little or no capital and have a higher return on investment.

Step 4

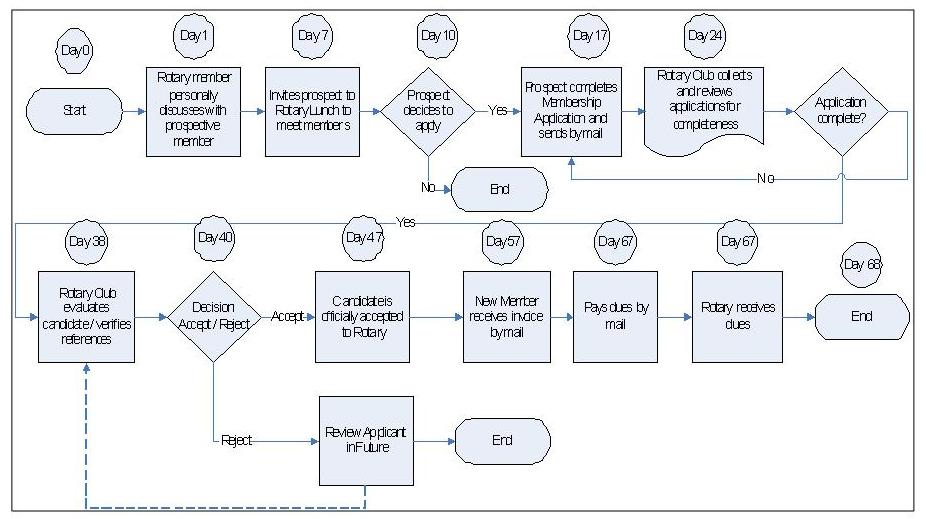

– Based on steps 2 and 3, map out a preliminary value stream of the particular process(s) you decide to focus on. The value stream represents the complete flow of materials and information required to deliver a product or service. A simple yet effective tool for understanding the value stream is a process flow map: a graphical depiction of the sequence of activities from start to finish that identifies owners, decision points, dependencies, etc. An end-to-end process flow map helps you identify gaps, bottlenecks, and redundancies. Use this information to quantify the waste, savings, or incremental revenue. Figure 4 is an example of a process map for becoming a Rotary Club member. Notice the elapsed time it takes from application submittal to candidate notification: 30 days. This appears to be a “bottleneck” that is hampering the throughput.

|

Figure 4 – click to view image (PDF)

Step 5

– Select the project as the beta test for your Productivity / Quality program. Secure initial support from co-workers who are willing to put in time to help you. The best folks are those who stand to gain the most from the improvement. Remember, the most knowledgeable people are generally those on your front line. I learned this while working in Japan. Build a compelling and concise business case. State the business problem, what you want to improve and by how much, the benefits, and a preliminary ROI / Payback Period. Present to senior management to get their buy-in.

Step 6

– Measure your key activities over time. Without data, it is impossible to perform the kind of analysis that will lead to good decisions. As Edwards Deming once said, “If you can’t measure it, you can’t manage it.”

Conclusion:

No Productivity program is easy to design and implement. There are no short-cuts or cookie cutter approaches. At the same time, it does not necessarily have to entail building a huge infrastructure or investing in lots of training and tools. The approach suggested above is one way to successfully “bootstrap” such a program. Start the program using these basic steps. Begin with a small, well-scoped, process-oriented project that has a high degree of success in terms of effectiveness, customer satisfaction and ROI. With your new found success, you’ll generate more momentum and interest by your co-workers and senior management. Before long, you’ll have proven the value of your proposed Productivity program.

References

1 Forrest W. Breyfogle III, “Starting a Six Sigma Initiative”, Ask the Expert, iSixSigma, January 2004.

2 Jim Biolos, “Six Sigma Meets the Service Economy”, Harvard Management Update, November 2002, pg. 3.

3 Forrest W. Breyfogle III, Integrated Enterprise Excellence: Volume II – Business Deployment, Bridgeway Books, 2008, pgs. 358 – 360.