![]() As Part of a Business Transformation and Enterprise Excellence strategy, how can the methodologies & tools of Operational Excellence be integrated into Business Strategy?

As Part of a Business Transformation and Enterprise Excellence strategy, how can the methodologies & tools of Operational Excellence be integrated into Business Strategy?

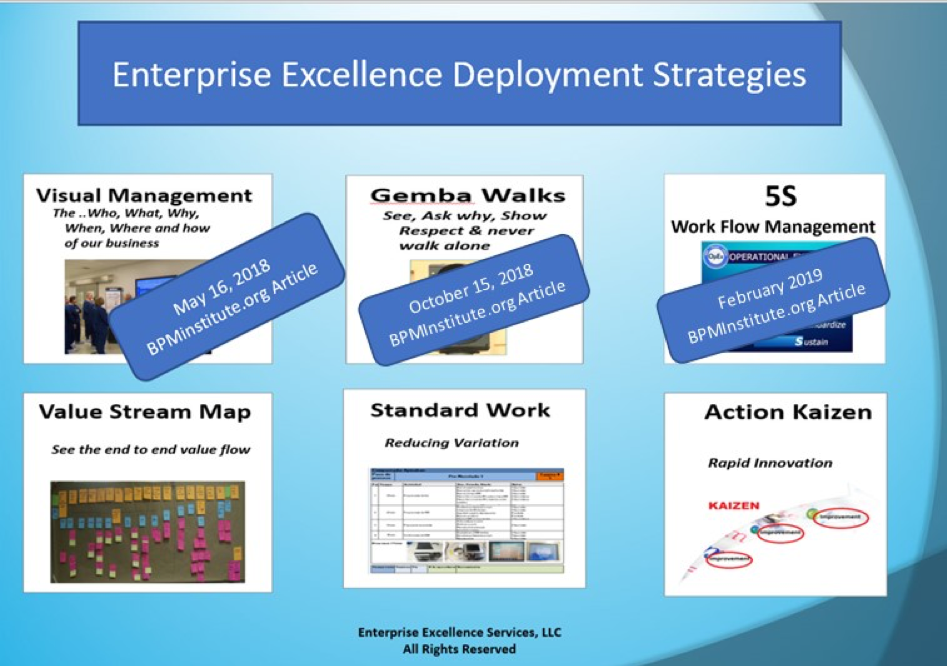

A foundation package was highlighted in a 16 MAY 18 BPM article 1 around 6 key methodologies … Visual Management, Gemba Walks, 5s, Value Stream Maps, Standard Work, & Kaizen Process Improvement. Visual Management and Gemba Walks have been previously discussed 1 & 2. Today’s article will be around 5S Work Flow Management.

![]() Tell me more about 5S Work Flow Management

Tell me more about 5S Work Flow Management

As one of the Foundational methodologies, 5S is a key skillset for Associates within the organization to leverage. It’s all about Engage, Empower and Enrich our people and cultivating Pride in the workplace through improved work flow and “Making our jobs easier”.

Early Beginnings of 5S:

- Origin is rooted in the works of two American pioneers

– Frederick W. Taylor, Scientific Management (circa 1915)

– Henry Ford, CANDO process (1920’s)

- Ford CANDO concepts were studied by Japanese managers and adapted at Toyota

- Popularized by Hiroyuki Hirano (1990) as 5S Methodology

“Scientific management is a theory of management that analyzes and synthesizes workflows. One of the earliest attempts to apply science to the engineering of processes and to management, it is sometimes known as Taylorism after its founder, Frederick Winslow Taylor. Taylor worked in manufacturing industries, especially steel, around 1910” 3

“The principles within 5S were being utilized early on by Henry Ford using CANDO (Cleaning up, Arranging, Neatness, Discipline and Ongoing improvement) in his manufacturing processes. In the 1950s, representatives from Toyota visited the Ford facilities to be trained in automotive mass production methods and later adapted the CANDO methods and applied them in their production facilities as 5S– Sort, Set, Shine, Standardize and Sustain. Throughout different companies, various words are used that have similar meanings. No matter what specific words are used to identify the steps in 5S, the purpose remains the same: create a clean, organized and efficient work environment.” 4

![]() What are the basics behind 5S?

What are the basics behind 5S?

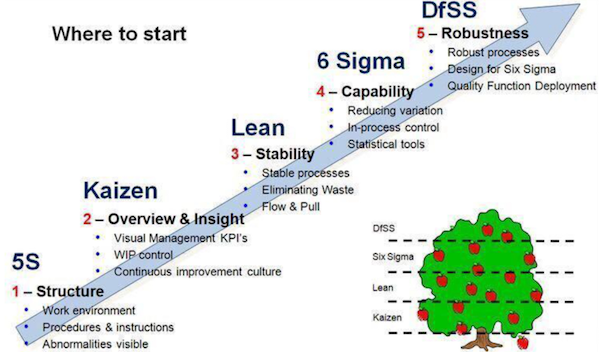

Starting with 5S as a Foundational Methodology, more specific techniques with OpEx can then come into play:

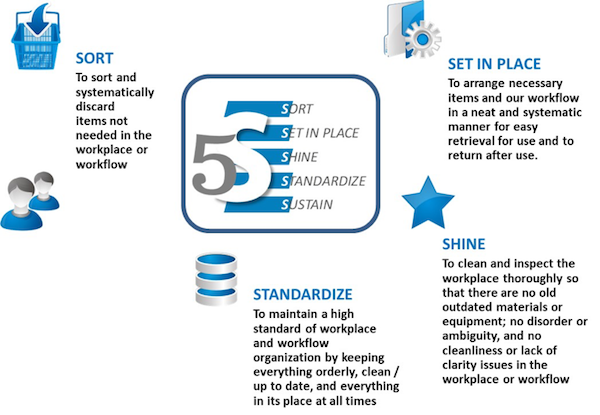

The five steps/pillars of 5S are:

- Seiri / Sort: Separating of the essential from the nonessential items and work flow management procedures and documents.

- Seiton / Straighten: Organizing only the essential’s so that everything has its place

- Seiso / Shine: Cleaning/decluttering the work area and work flow process; resetting around the essential’s only.

- Seiketsu / Standardize: Establishing a system to maintain the work area and work flow process to formalize 5S into “the way we work”.

- Shitsuke / Sustain: Establishing the work area/work flow through organized, common sense usage & design that can be easily maintained and visually verified. Inspection and verification that the 5S flow is maintained. An added bonus is to integrate a safe work environment (Safety) into all we do (sometimes referred to as the “Sixth S”).

In a more visual view:

![]() What/Where can the concepts of 5S be used?

What/Where can the concepts of 5S be used?

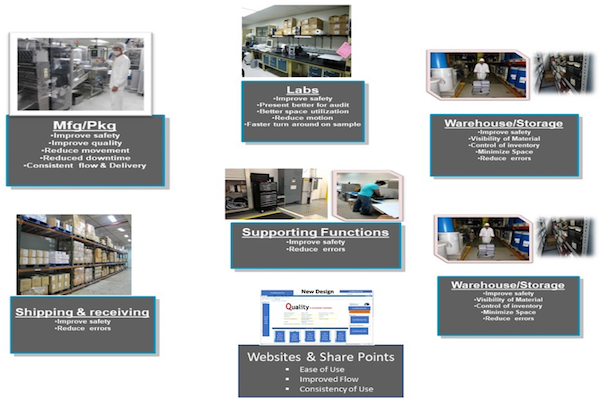

There are numerous articles and books on 5S deployment, methodology, tools and techniques that can be located by simple web searches5. The intent of this article is to show the HOW and WHERE of 5S in the workplace with examples of 5S successful deployment, and how it improves the overall workplace for everyone.

![]() What are some examples of 5S?

What are some examples of 5S?

Visual Examples6 include:

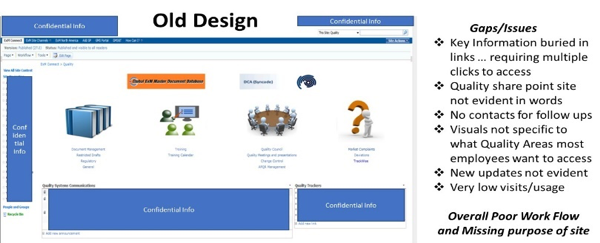

Share Point site 5S Redesign

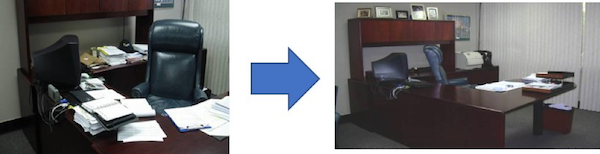

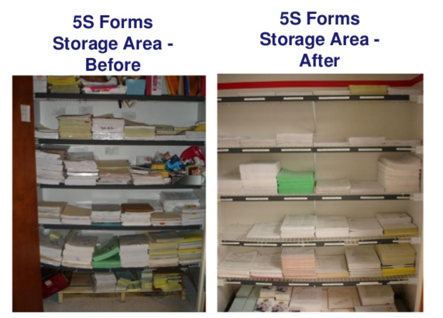

Office 5S Improvement for Leadership & Associates

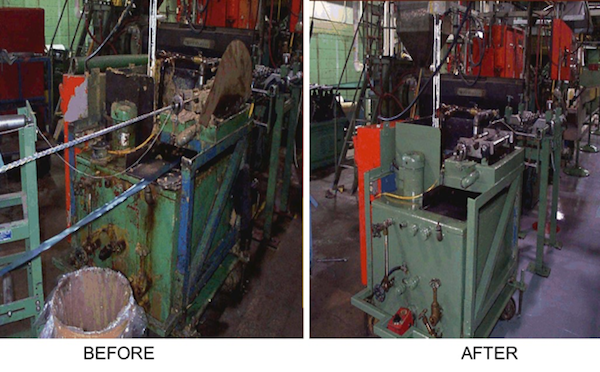

Manufacturing Examples

Operations

Material Supplies

Spare Parts

Tools

Warehouse – 5S Organized & Standardized with Marked Areas

Maintenance Area

Laboratory 5S Storage 5S

![]() What are some TIPS for a successful 5S?

What are some TIPS for a successful 5S?

A 5S & Visual workplace provides:

1. Engage and Empower Our People to own and implement 5S –

Pride in the workforce

2. Managers and Leaders as coaches and mentors

Full Support of 5S and any changes or expenditures to implement

3. Maintain an unwavering focus on safety and quality

4. Overarching umbrella for how work should be organized

5. Increase productivity and efficiency in a better working environment – Less time looking and waiting

Look for future articles on Enterprise Excellence Business Process Management as well as deployment strategies as shown below:

References:

1. “Visual Management in Enterprise Excellence Deployment” , 16MAY18 BPMInstitute.org article https://www.bpminstitute.org/resources/articles/visual- management-enterprise-excellence-deployment

2. “Gemba Walks in Enterprise Excellence Deployment,” 5OCT18 BPMInstitute.org article https://www.bpminstitute.org/resources/articles/gemba-walks-–- foundational-methodology-enterprise-excellence-deployment

3. Frederick Taylor & Scientific Management, https://en.wikipedia.org/wiki/Scientific_management#Relationship_to_Fordism

4. Quality One International, https://quality-one.com/5s/

5. Articles and books on 5S deployment, methodology, tools and techniques include, but are not limited to:

- “5S Simplified: Lean Manufacturing Series” by Agathinian K

- “Process Implementation through 5S : Laying Foundation for Lean” by Drew Willis

- “5S for Supervisors (Lean)” by Ade Asefeso

- “The 5S Playbook: A Step-By-Step Guideline…” by Chris A Ortiz

- “5S for Operators: 5 Pillars of the Visual Workplace” by Hiroyuki Hirano

- “5S Made Easy: A Step-By-Step Guide…” by David Visco

6. Visual Before-After Pictures sources include:

https://www.bing.com/images/search?q=good+examples+of+5s&qpvt=good+examples+of+5s&FORM=IQFRML